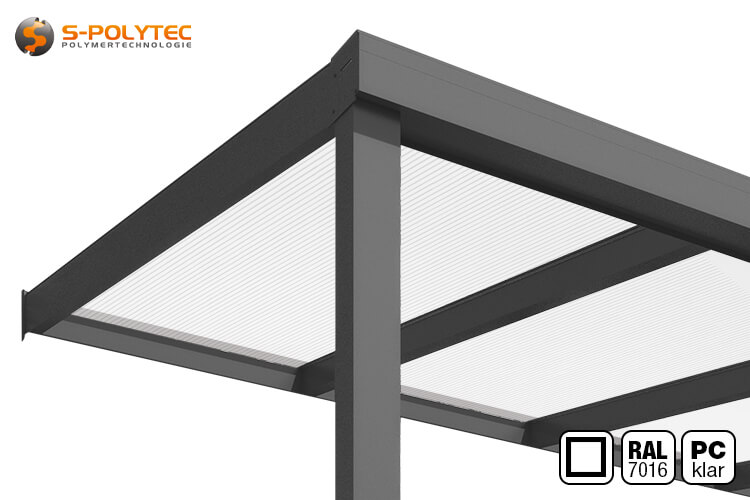

Terrace roof anthracite (polycarbonate transparent)

Our terrace roofing in anthracite with transparent 16mm double-skin polycarbonate sheets and powder-coated aluminum profiles can be configured online from 3m to 12m wide and 2m to 5m deep at affordable prices.

✓ Square or rounded profiles

✓ Powder-coated surfaces

✓ 16mm double-skin sheet (clear)

✓ EN AW 6063-T6 Aluminium

✓ Snow load zone 1

The aluminum terrace roof is available in RAL7016 with either square or rounded profiles.

The item is in stock

Dispatch within 8 - 12 weeks

- Configure Roofing

0,00 € / pc.

0,0000 kg / pc.

All prices include 19% VAT.

- Description

Aluminium patio roof in anthracite with transparent polycarbonate

16 mm double-skin sheets ✓ Profiles made from 6063-T6 aluminium ✓ Easy installation ✓

With our made-to-measure patio roofing in anthracite and shatterproof covering made of high-quality polycarbonate in a transparent design, we offer you the opportunity to customise your roofing to your individual needs with just a few clicks. With the simple configuration of width, depth and type of profile design, you can put together the perfect canopy for any patio in no time at all. With a high-quality powder coating in timeless anthracite grey (RAL 7016), the canopy blends in with any architectural style. The lightweight covering made of transparent double-skin polycarbonate sheets with a high light transmission of approx. 70% protects against UV radiation, rain, snow and hail and is suitable for areas in snow load zone 1. Some size combinations are even approved for snow load zone 2.

The patio cover is supplied complete with all the necessary components for easy self-assembly.

The size of the made-to-measure patio covers can be configured from a discreet 6m2 for a three-meter-wide and 2-meter-deep cover to 12m wide and 5m deep, which corresponds to a roof area of an incredible 60m2. You can also choose the shape of the gutter cover between a flat design for an angular appearance of the roof front or a rounded front profile. All aluminium profiles are made from particularly high-quality EN AW 6063-T6 aluminium. This is an extremely resilient aluminium alloy with outstanding corrosion resistance. All profiles are also finished with an easy-care and robust powder coating in anthracite, which does not lose its intensity or fade due to its excellent UV and weather resistance.

NOTE: Our terrace roofs are assembled individually according to your configuration for length, width and profile shape and the panels are already cut to size, and each profile is carefully loaded onto the lorry by hand. For this reason, a delivery time of approx. 8 - 12 weeks is necessary. Delivery is carried out by a forwarding agent and is also unloaded by hand and brought to the garden on request. The scope of delivery and the total weight can vary considerably depending on which size combination you have chosen.

Features of the patio roof in anthracite

Our patio roofs are made exclusively from high-quality aluminium. In contrast to many suppliers, we use a high-quality EN AW 6063-T6 aluminium alloy, which is around a quarter more stable and resilient than the EN AW 6060-T6 aluminium from which most patio roofs are made. The higher quality alloy allows us to achieve a slimmer look and increase the distance between the individual support posts. Depending on the combination of your patio roof, in addition to the powder-coated aluminium profiles in anthracite, the delivery also includes additional steel reinforcement profiles, which are simply inserted into the cavities provided in the rafters and the front gutter profile. This increases the load-bearing capacity of the roofing so that all roofing systems can be approved for use in snow areas with snow load zone 1. Individual configurations are even approved for regions with a higher snow load (snow load zone 2). The additional information contains specific information on the rapid load zone and its suitability for each possible combination of roof depth and roof width.

All aluminium profiles and covers are finished with a satin matt powder coating in anthracite (RAL7016). This not only looks particularly attractive, but also has a further effect on the already excellent corrosion resistance of the aluminium alloy used. All visible screws are also painted in the same RAL colour to achieve a homogeneous overall look. This is a UV and weather-resistant paint finish that does not fade even in intense sunlight, so that you can enjoy your patio roof for many years to come.

The covering of the patio roof consists of transparent double-skin polycarbonate sheets with a total thickness of 16 mm. This is a lightweight plastic that is particularly impressive due to its impact resistance. Unlike acrylic glass, polycarbonate is considered shatterproof, so you don't have to worry about the roof being damaged by hail. For unclouded outdoor use, we use a UV-stable type of double-skin sheet. This prevents the sheets from becoming brittle or yellowing due to UV rays. Similar to the aluminium profiles as the load-bearing structure of the roofing, the polycarbonate sheets are also adapted to the roof depth you select. This means you don't have to pick up a saw and cut the sheets to size yourself, as we have already done this for you.

Rain and meltwater drainage is completely concealed within one of the two outer support posts so as not to spoil the attractive appearance of the beautiful roofing. Everything needed for drainage is included in the scope of delivery, from the downpipe to the outlet elbow and the leaf catcher to protect against blockages caused by leaves. Depending on the type of installation, the rainwater can be drained through a hole drilled with a Ø 60 mm hole saw in the post just above the ground or, with the help of an optionally available concrete base with integrated drainage, underground so that the post remains intact. In addition to many other advantages when installing the canopy with our concrete bases, the integrated drainage offers the option of draining the rainwater underground through pipes into a rainwater tank and using it for watering the garden as required.

Optional accessories

- Concrete base for easy installation of the support posts

- Concrete base with integrated drainage

- LED lighting in RAL7016 (dimmable, incl. remote control)

Installation of the patio roof with transparent polycarbonate covering

After you have adapted your patio roof to your personal wishes and ideas in terms of width, depth and profile shape, the aluminium profiles with anthracite grey powder coating are commissioned in the appropriate size according to your configuration. The same applies to the double-skin sheets made of transparent polycarbonate, which are cut to the required depth before delivery. Everything is then carefully packed and delivered together with the installation material and all other components, such as seals, cover panels, support posts or individual parts for concealed drainage.

For roofings with a width of up to 6 metres, all aluminium profiles are supplied in exactly the required length, which keeps the installation effort to a minimum. For roofs wider than 6 metres, the wall connection profile, the gutter profle and the selected decorative front panel are each connected by two profiles in order to achieve the large overall width. These are supplied in standard lengths of 4.06, 5.06 or 6.06 metres, which still need to be shortened using a cross-cut saw. For patio roofs from 11.06 metres wide and a depth of 4.5 metres or higher, these three profile variants even consist of three linked profiles each, which must be adjusted to the final dimensions. All other profiles and covers, on the other hand, are supplied in the exact size required for your configuration.

IMPORTANT! For terrace roofs with a width of more than 6 metres, the additional instructions in the assembly instructions, which contain important detailed measurements for shortening the profiles, must be taken into account before starting assembly.

The support posts are also excluded from the profiles that have already been cut to size.. The length of the posts can vary depending on whether the installation height on the wall side is determined by the architectural conditions (e.g. because the wall connection profile is to be installed on the balcony projection) or the clearance height between the posts is decisive for you. Even a gradient from the wall to the terrace, as well as uneven ground between the respective support posts, can mean that the support posts have to be shortened individually. Here too, the illustrated instructions will guide you step by step through the process. Graphics for determining the distance from the wall and the distance between the posts, as well as a table with the installation heights of the wall profile, also make installation easier. Depending on the size, a little manual dexterity and the right tools, installation can easily be completed within a day, so that you can start marking the wall connection profile in the morning and have a barbecue with your helpers under the finished patio in the afternoon.

You can view, download or print out the assembly instructions at any time - even now - in the Downloads section. With detailed and easy-to-understand illustrations, they guide you step by step through the assembly process, which can essentially be summarised in seven assembly steps.

The 7 essential installation steps for the patio roof

- 1. Mounting the wall connection profile on the masonry

- 2. Positioning the support posts and shortening if necessary

- 3. Fitting the channel to the support posts

- 4. Fitting the side rafters to the wall connection profile and outer support posts

- 5. Preparing, inserting and screwing the internal rafters

- 6. Preparing and inserting the transparent polycarbonate sheets and rafter covers

- 7. Installation of the internal drainage

Each of these points requires a different number of intermediate steps, which are repeated a different number of times depending on the width of the roofing. This applies in particular to the preparation of the inner rafters and rafter cover, into which the rubber seals must be inserted. If additional lighting is to be installed, this is also one of the preparatory measures for the inner rafters.

Assembly tools required

- Circular saw or chop saw with metal saw blade

- Drilling machine

- Hammer drill Ø8 mm (*) for stone/concrete

- Cordless screwdriver

- Metal drills in Ø 9mm(*), 5mm and 3,5mm

- 13mm spanner or reversible ratchet with socket

- 5 metre tape measure

- Hole saw Ø 60mm for metal for drainage in channel and support post

- Hole saw Ø 28mm for metal (required with optional lighting)

- Cutter knife for cutting the rubber seals to length

- Spade or shovel (for excavation of the foundation)

- Silicone gun

- Rubber mallet

- Spirit level

NOTE: Ø8mmx60mm impact dowels are supplied for installation in solid stone or concrete. If it is necessary to adapt the fasteners to ensure secure installation of the wall connection profile, the drill bits, which are marked with an asterisk (*) in the required tools, must be used. They must be adapted to the size of the fasteners. The diameter of the metal drill bit should be one millimetre larger than the diameter of the dowel fastening.

We also recommend the use of ladders when installing the patio covers. It is also necessary to temporarily relieve the support posts until a poured foundation has hardened, and to install and align the support posts and the front profile with drainage channel.

Technical data of the patio roof

- Material (profile): Aluminum (EN AW 6063-T6), powder-coated

- Colour (profile): Anthracite grey (RAL7016)

- Shape (profile): Square or rounded

- Material (covering): Polycarbonate (16mm double-skin sheet)

- Color (covering): Transparent

- Light transmission: 70%

- Roof width: from 3,06m to 12,06m

- Roof depth: from 2,00m to 5,00m

- Clearance height: max. 250cm

- Number of rafters: varies (width in meters + 1)

- Rafter spacing: 1 Metre

- Number of posts: varies (from 2 upto 5)

- Snow load zone: Snow load zone 1 (partly 2)

- Drainage: Yes, fully integrated in the post

- Corrosion resistance: Yes

- UV resistance (color): Yes (10 year warranty)

- UV resistance (covering): Yes

Care and maintenance of the patio roof

Our patio covers are particularly maintenance-free. This is due to the high-quality aluminium alloy with outstanding corrosion resistance and the robust powder coating in anthracite (RAL7016). Even with the transparent polycarbonate cladding, nothing else needs to be done after installation. If necessary, occasional cleaning may be required to maintain the attractive appearance and translucency of the panels. We recommend using gentle cleaning agents and a soft, lint-free cloth. Harsh, aggressive cleaning agents or abrasive cleaners, as well as hard sponges, should be avoided instead, as this can damage the painted surfaces and leave scratches in the polycarbonate roof.

We recommend using a high-pressure cleaner to remove unsightly dirt from the transparent roof covering. Never step directly on the roof covering, but place a wide board on the roof to distribute the weight. To prevent the coated profiles from being damaged by the board, a cloth should be placed between the board and the rafter covers. It may also be useful to remove leaves from the leaf catcher and the gutter at regular intervals to ensure smooth drainage of the roof.

- Additional Information

Additional Information

Product-ID A-PCT Delivery Time Dispatch within 8 - 12 weeks Material Aluminium (EN AW 6063-T6) Width No Depth No Covering Polycarbonate transparent Glass thickness 16mm double-wall sheet Property Roofing for self-assembly Number of posts varies Number of rafters varies Snow load zone Snow load zone 2 Color Grey Color accuracy Production according to RAL color system RAL color code RAL7016 Color designation Anthracite grey - Reviews

- Attachments