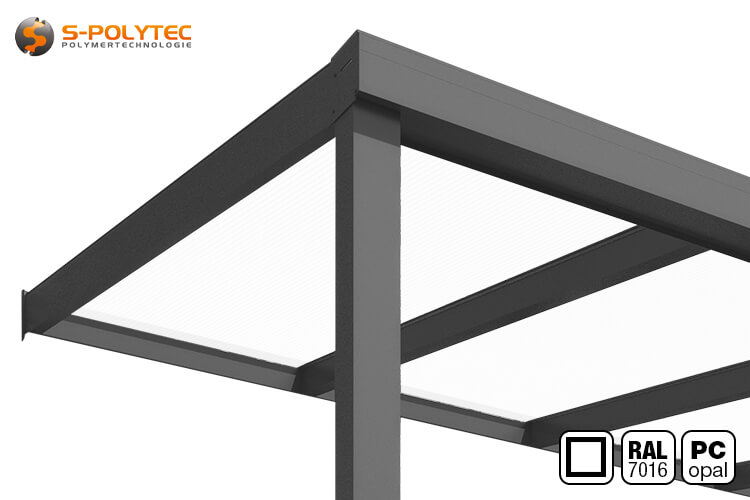

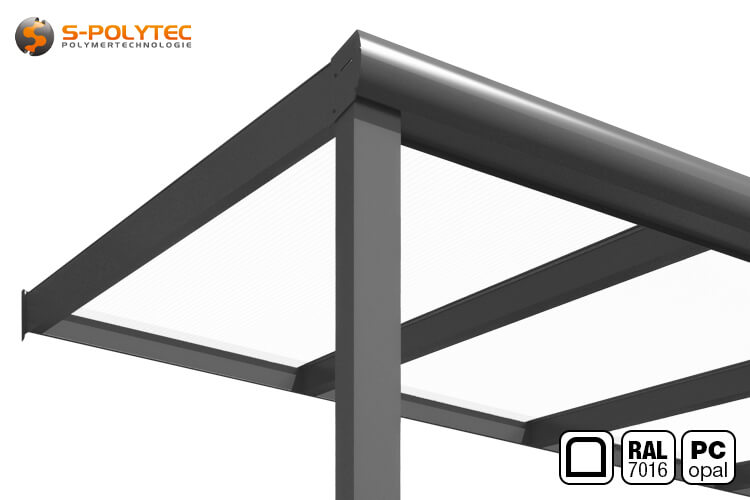

Terrace roof anthracite (opal polycarbonate)

Our terrace roofing in anthracite with covering made of shatterproof double-skin polycarbonate sheets in opal is optionally available with angular or rounded profiles made of powder-coated aluminum.

✓ Angular or rounded profiles

✓ Powder coating in RAL 7016

✓ 16mm twin-wall sheet (opal)

✓ EN AW 6063-T6 Aluminium

✓ Snow load zone 1

The made-to-measure aluminum terrace roof can be configured in RAL7016 from 3.06 x 2.00m to 12.06 x 5.00m.

The item is in stock

Dispatch within 8 - 12 weeks

- Configure Roofing

0,00 € / pc.

0,0000 kg / pc.

All prices include 19% VAT.

- Description

Patio roof in anthracite with polycarbonate panels in opal

Opal twin-wall sheets ✓ Powder-coated aluminum profiles ✓ Easy installation ✓

Our made-to-measure aluminum patio roofs with powder coating in anthracite (RAL7016) have a covering made of shatterproof polycarbonate sheets in opal. The milky opaque double-skin sheets with a total thickness of 16 mm combine good privacy protection with good light transmission of 54%, so that you don't have to sit in the dark even in poor lighting conditions. In addition to the choice of width, you can also select different roof depths and two different profile shapes during configuration, so that you can put together the patio cover to suit your requirements in terms of size and design and experience a completely new feeling of outdoor living. From a compact canopy 3 meters wide and 2 meters deep, even very large patio roofs can be covered with our high-quality aluminium patio roofs. Thanks to the combination of EN AW 6063-T6 aluminum alloy and lightweight polycarbonate sheets, even a wide up to 12 or depth up to 5 meters are possible.

Conveniently configure your dream roof online with just a few clicks and experience your garden in a completely new way.

With our patio cover, you can enjoy your garden at any time of year - regardless of whether the sun is shining, it is raining or snowing. Depending on the design and size, the unobstructed view of the garden is not even restricted by intermediate supports. Whether and how many supports are required varies depending on the roof width, depth and snow load zone suitability. All polycarbonate patio roofs are approved for snow load zone 1. Some size combinations are even suitable for regions with higher snowfall in snow load zone 2. All aluminum profiles, covers and even the screws in the visible area are equipped with a high-quality powder coating in RAL7016 (anthracite grey). A very popular shade of gray that can be integrated into any architectural style. A special paint with very good UV and weather resistance is used to ensure that the color withstands the demands of weather-related influences and does not fade due to UV radiation.

NOTE: The delivery time for our patio roofs is approx. 8 - 12 weeks and is due to the individual commissioning and loading, as the individual components are loaded onto the lorry one by one by hand with the utmost care. Due to the weight and length of the profiles, they are delivered to the terrace by a haulage contractor.

Properties of the opal patio roof in anthracite

As the name suggests, the roof structure of our aluminum patio roofs with polycarbonate roofs is made of aluminum. All profiles, supports and profile covers are made from a particularly high-quality EN AW 6063-T6 aluminum alloy. In contrast to the more common 6060-T6, this alloy is more stable and resilient, which not only has an effect on the durability of the roofing, but is also important from an aesthetic point of view, as the greater stability means that the posts can be spaced further apart, so that roof widths of up to 6 meters are possible with just two outer support posts, depending on the depth. Roof widths of more than 6 metres require one or more intermediate supports. However, you can see the exact number of support posts in the additional information once you have selected the size. Some roofs, but not all possible combinations of depth and width, are supplied with additional profiles to reinforce the inner rafters and the gutter. These can be easily inserted into the corresponding cavities. For the inner rafters, these are additionally fixed in place with self-tapping screws to prevent them from slipping so that everything stays in place. The reinforcements are necessary to increase the load-bearing capacity with long rafter lengths and also allow us to increase the spacing between the support posts so that fewer intermediate posts obstruct the unobstructed view of the garden. For some roofs, the additional reinforcement profiles also increase the permissible snow load, so that the roofs can be used not only in regions with low snowfall (snow load zone 1, also applicable to the whole of the Netherlands and Belgium), but also in snow load zone 2, which covers the widest parts of Germany. Information on the approval of the respective snow load zone can be found in the Additional information tab after selecting the size.

Aluminum is an outstanding material with excellent corrosion resistance and does not require as much maintenance as comparable structures made of wood. However, bare aluminum is not as visually appealing as a patio cover in the very popular anthracite color. For this reason, all profiles and covers are powder-coated. The grey shade of the satin matt coating corresponds to RAL color 7016 (anthracite grey). Even the screws that are used in the visible area have a head coating in the corresponding color so that no silver screws spoil the perfect appearance of the patio roof. Powder coating, which is baked onto the surface in a special process using high heat, creates a flawless top coat of paint, which is also characterized by very good resistance to UV radiation and weathering. So you don't have to worry about the dark gray fading over time.

The roofing sheets are made of opal polycarbonate. To be more precise, these are double-skin sheets with a total thickness of 16 mm. The main advantages of this type of plastic roof covering are its significantly lower weight and very high impact resistance, as polycarbonate is a break-resistant plastic. The milky opaque sheets offer a perfect mix of privacy protection and good light transmission. Particularly in apartment buildings with multi-storey apartments, it may not be desirable for nosy neighbours to keep a constant eye on the goings-on below. Here, opal roofing offers significant added value in terms of increased privacy. In addition, direct sunlight is avoided and bathes the patio in a pleasantly diffuse, soft light. However, the other side of the coin should not be ignored, as the light transmission of an opal twin-wall sheet is also slightly lower at 54% than that of an equivalent transparent covering, which has a light transmission of 70%. In most cases, however, this difference is barely noticeable and can even be an advantage when the sun is shining and you don't want to be dazzled on the patio.

To avoid disfiguring the attractive design of the canopy with ugly pipes, the drainage is fully integrated. This means that the rain gutter, which is covered by the decorative profile, is barely noticeable as such. The leaf catcher and the PVC pipe laid in the support post are also invisible unless you look down on the roof from a bird's eye view. However, the water has to come out somewhere, so a hole with a diameter of 60 mm has to be drilled or sawn into the post. With the 90° PVC bend supplied, the rainwater can then be drained to one side of the support post so that it can seep into the ground. Thanks to a concrete base with integrated drainage, the drainage can even be completely concealed underground so that the support post remains intact. However, this is not included in the standard scope of delivery and can be ordered directly on request.

TIP: If the water is drained above or below ground into a rainwater collection barrel, it can be used for watering the garden or occasionally cleaning the roof.

Optional accessories

- Concrete base for easy installation of the support posts

- Concrete base with integrated drainage

- LED lighting in RAL7016 (dimmable, incl. remote control)

Installation of the patio roof with opal polycarbonate

Before you start configuring the anthracite gray patio roofing with opal double-skin sheets, we recommend taking a look at the installation instructions. These are available to download at any time in the "Data sheets" tab. Please pay particular attention to the installation requirements for the wall and ground conditions in order to rule out possible complications during installation in advance.

As you can see from the detailed illustrated instructions, this involves a manageable amount of work. With our made-to-measure patio roofs, we make it as easy as possible for you, as most profiles are already comes in the right size for you. The opal polycarbonate twin-wall sheets are already cut to the roof depth you have configured. With the right tools, a little manual dexterity and a helping hand, installation takes just a few hours. Of course, the duration also depends on the specific size of the roof and the preparations, such as the earthworks, pouring and hardening of the concrete foundation (unless our prefabricated concrete bases are used).

The finished patio roof in 7 assembly steps

- 1. Fastening the wall connection profile to the masonry

- 2. Measuring, cutting and positioning the support posts

- 3. Screwing the drainage channel to the support posts

- 4. Fitting the side rafters to the wall connection profile and the support posts

- 5. Preparation and installation of the interior rafters

- 6. Preparation and installation of opal polycarbonate sheets and rafter covers

- 7. Installation of the internal drainage

Each of these points requires a different number of intermediate steps, which are repeated a different number of times depending on the width of the roofing. This applies in particular to the preparation of the inner rafters and rafter cover, into which the rubber seals must be inserted. If additional lighting is to be installed, this is also one of the preparatory measures for the inner rafters.

For roofs up to 6 metres wide, all profiles, covers and polycarbonate sheets for installing the roof are delivered already cut to size. For wider roofs, the wall connection profile and the drainage gutter, as well as its decorative panel, consist of two individual elements. For Terrace roofs from 11 metres wide and 4.5 metres depth, there are even three individual profiles, each of which must be shortened slightly with a cross-cut saw before they are installed

IMPORTANT! For roofings over 6 metres wide, the additional instructions must be taken into account before assembly.

This also does not apply to the support posts with a length of 250cm, as the decision as to how high these need to be depends on various factors. Either the installation height of the wall connection profile is determined by the local conditions, so that the clearance height of the support posts must be adapted to this dimension, taking into account the roof pitch, or a specific clearance height between the posts is required. In both cases, the table on the penultimate page of the installation instructions with the corresponding dimensions is a good aid. In addition, uneven ground and slopes along the roof width, as well as from the building to the front part of the terrace, also play a significant role in the respective cutting of the support posts. Cutting to size is best achieved with a mitre saw. In an emergency, however, a hand-held circular saw with a saw blade for metal is also useful.

Assembly tools required

- Circular saw or chop saw with metal saw blade

- Impact drill

- Hammer drill bit for stone/concrete in Ø8 mm(*)

- Cordless screwdriver

- HSS drill bit for aluminum in Ø 9mm (*), 5mm and 3.5mm

- 13mm wrench or reversible ratchet with socket

- 5 meter tape measure

- Hole saw Ø 60mm for aluminum for drainage in gutter and support post

- Hole saw Ø 28mm for aluminum (required with optional lighting)

- Knife or sharp scissors to cut the rubber seals to length

- Spade or shovel (for earthworks with underground foundations)

- Silicone gun

- Rubber mallet

- Spirit level

NOTE: The scope of delivery includes everything you need to install your new patio roof. This also includes a sufficient number of impact dowels to attach the wall profile to the house wall. In some cases, however, the supplied fixings are not perfectly suitable, so alternative fixings must be selected. If this is the case, suitable drill bits for the mounting surface and the metal drill bit for the aluminum profile must of course be adapted to the diameter of the screws. We recommend always drilling the profile one millimeter larger than the screw diameter.

To simplify the installation of the gutter on the support posts, it should be additionally supported from below in the meantime. As soon as the supports are connected to the wall connection profile by the lateral roof beams, the temporary support is no longer necessary, as the fixed screw connection means that the front part with support posts and gutter can no longer topple over.

Technical data of the patio roof

- Material (profile): Aluminum (EN AW 6063-T6), powder-coated

- Colour (profile): Anthracite grey (RAL7016)

- Shape (profile): Square or rounded

- Material (covering): Polycarbonate (16mm double-skin sheet)

- Color (covering): Opal

- Light transmission: 54%

- Roof width: from 3,06m to 12,06m

- Roof depth: from 2,00m to 5,00m

- Clearance height: max. 250cm

- Number of rafters: varies (width in meters + 1)

- Rafter spacing: 1 Metre

- Number of posts: varies (from 2 upto 5)

- Snow load zone: Snow load zone 1 (partly 2)

- Drainage: Yes, fully integrated in the post

- Corrosion resistance: Yes

- UV resistance (color): Yes (10 year warranty)

- UV resistance (covering): Yes

Care and maintenance of the patio roof

Our patio covers are made of powder-coated aluminum and are therefore particularly maintenance-free. The opal polycarbonate roof panels are also extremely low-maintenance, so that no further maintenance is required here.

The easiest and most efficient way to clean a patio roof with opal polycarbonate roofing is to use a high-pressure cleaner. This is very suitable for spraying down the panels from above and also for removing dust, dirt and cobwebs from the profiles. However, care must be taken when cleaning the rafters from below if they are fitted with additional lighting or other electrical accessories (under-glass awning, patio heater, etc.). There is a risk of electric shock. Instead, use clear water or a mild soap solution and a soft cloth for cleaning. Never use aggressive cleaning agents or cleaners with abrasive particles. Abrasive sponges are also too aggressive and can damage the silky matt surface of the anthracite gray powder coating.

To ensure that rainwater drains away, we recommend regularly checking the drainage channel and the leaf catcher. If necessary, remove debris and leaves so that the drain does not become blocked.

Regardless of whether the roof is to be cleaned from above or the gutter. We strongly advise against standing directly on the twin-wall sheets or the rafters. Instead, always use a wide base to distribute the weight better. A simple board may suffice here, but a non-slip base should be used between the board and the roof to prevent damage and scratches to the immaculate surfaces.

- Additional Information

Additional Information

Product-ID A-PCO Delivery Time Dispatch within 8 - 12 weeks Material Aluminium (EN AW 6063-T6) Width No Depth No Covering Polycarbonate opal Glass thickness 16mm double-wall sheet Property Roofing for self-assembly Number of posts varies Number of rafters varies Snow load zone Snow load zone 2 Color Grey Color accuracy Production according to RAL color system RAL color code RAL7016 Color designation Anthracite grey - Reviews

- Attachments